As can be seen, labor is the cost that mainly determines the transformation or Certified Public Accountant conversion process, then from here on there must be costs of a similar nature or of a similar impact. These costs are mainly made up of two costs, on the one hand that of labor and on the other hand that related to the transformation or manufacturing process. Factory outlay are classified in the regular way as indirect costs or overheads. One of the most important pieces of information you can get from the values of conversion cost is whether your marketing campaign is profitable and, therefore, worth the effort.

Fluctuating Labor Costs – Some Common Challenges Associated with Calculating Conversion Cost

Understanding and calculating this cost is essential for businesses to ensure they can accurately price their products and manage AI in Accounting their operations efficiently. This article will explore how the Conversion Cost Calculator works, explain the formula, offer an example, and provide helpful insights for users. Therefore, once the batch of sticks gets to the second process—the packaging department—it already has costs attached to it.

2 Conversion Cost vs. Total Manufacturing Cost

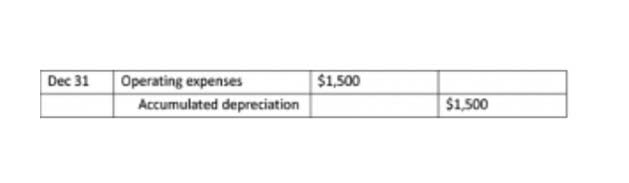

The manufacturing sector analyses both prime costs and conversion costs to measure efficiency in the production of a product. Prime costs and conversion costs include some of the same factors of production expenses, but each provides a different perspective when it comes to evaluating production efficiency. This includes rent, utilities, machine repairs, and any other expenses incurred within the factory. In some industries, conversion costs, including labour expenses, can exceed the total expenses on raw materials. In the food industry, converting raw food materials into edible food items is labour-intensive and requires specialised machinery.

- Technology has made it easier to make changes to conversion cost calculations.

- These individuals contribute their time, skills, and effort directly to the manufacturing of goods.

- The cost of manufacturing a product cannot be traced to just one unit in the process.

- Or, a block of wood is placed on the assembly line (where worked then convert it into the finished product).

- Manufacturers may need to invest in modern accounting systems to improve the accuracy of their conversion cost calculations.

- It provides insights into the efficiency and effectiveness of the production process.

Process Improvements – Why is Conversion Cost Important in Manufacturing

The conversion cost, when used in conjunction with prime cost, helps reduce waste and gauge other operational inefficiencies that may be present within the manufacturing facility. If your conversion goal is more than just a website visit, look at your landing pages. Confirm that the landing page is relevant to the viewers and encourages them to complete the action that is your goal. For example, if your conversion metric is signing up for your email list, the signup form should be prominent. How to assess conversion cost if it is watching a video, the video should be prominent. Yes, conversion costs are relevant for decision-making in a manufacturing business.

Prime costs are reviewed by operations managers to ensure that the company is maintaining an efficient production process. A positive variance indicates that the actual conversion costs exceeded the budgeted costs, while a negative variance suggests that conversion costs the actual costs were lower than the budgeted costs. Conversion costs are reported in cost of goods manufactured (COGM) statements, providing stakeholders with transparency into production expenses. Suppose an e-commerce company notices a high bounce rate on its product pages. By optimizing the landing page design, simplifying the checkout process, and adding customer testimonials, they reduce bounce rates by 20% and increase conversions by 15%. Total Conversion Cost refers to the overall expenses incurred during the process of converting leads or prospects into paying customers.

- The company can then explore ways to streamline the labor-intensive processes, negotiate better labor rates, or implement training programs to enhance workforce productivity and reduce conversion costs.

- Alternatively, the company may reduce the conversion cost by implementing cost-saving measures, such as automation, to maintain the current price point.

- This can make it difficult to accurately predict or allocate labor costs, impacting the accuracy of conversion cost calculations.

- Some other examples of manufacturing overheads are insurance, building maintenance, machine maintenance, taxes, equipment depreciation, machining, and inspection.

- By calculating the contribution margin per unit of conversion cost, managers can determine the profitability and relative attractiveness of different products or product lines.

- In this article, we’ll delve into what conversion costs are, provide the formula for calculating them, and offer examples to illustrate their application.

Conversion Cost Definition, Formula & Examples

- For example, if the direct labor cost is $50,000 and the manufacturing overhead cost is $40,000, the total conversion cost is $90,000.

- Conversion costs are calculated in order to know the cost per unit, which assists the company in deciding a price for the product.

- It is easier to track the materials and conversion costs for one batch and have those costs follow the batch to the next process.

- Direct material cost encompasses the expenses related to raw materials used in production.

- It just doesn’t make sense to track how many milliseconds each worker spends on each product unit among a sea of identical product units moving down an assembly line.

- In summary, understanding the factors affecting conversion cost allows businesses to make informed decisions, optimize processes, and enhance profitability.

- Conversion costs are important for cost accounting and management because they help to measure the efficiency and profitability of the production process.

Process costing firms usually find it inefficient to trace any costs to individual product units, including costs that are traditionally considered direct materials or direct labor. It just doesn’t make sense to track how many milliseconds each worker spends on each product unit among a sea of identical product units moving down an assembly line. This information helps managers know where to focus their attention when planning, directing and controlling costs. Conversion costs significantly impact product pricing as they form a substantial portion of production expenses. Businesses must incorporate these costs into pricing models to maintain profitability and competitiveness.